An inoperative equipment flow chart is a systematic guide used in aviation maintenance to assess and decide the course of action for inoperative equipment on an aircraft. Here, inoperative equipment can refer to any part of the aircraft that is not functioning as per its design. This could range from minor issues like a burnt-out cabin light to more significant problems like malfunctioning navigation systems.

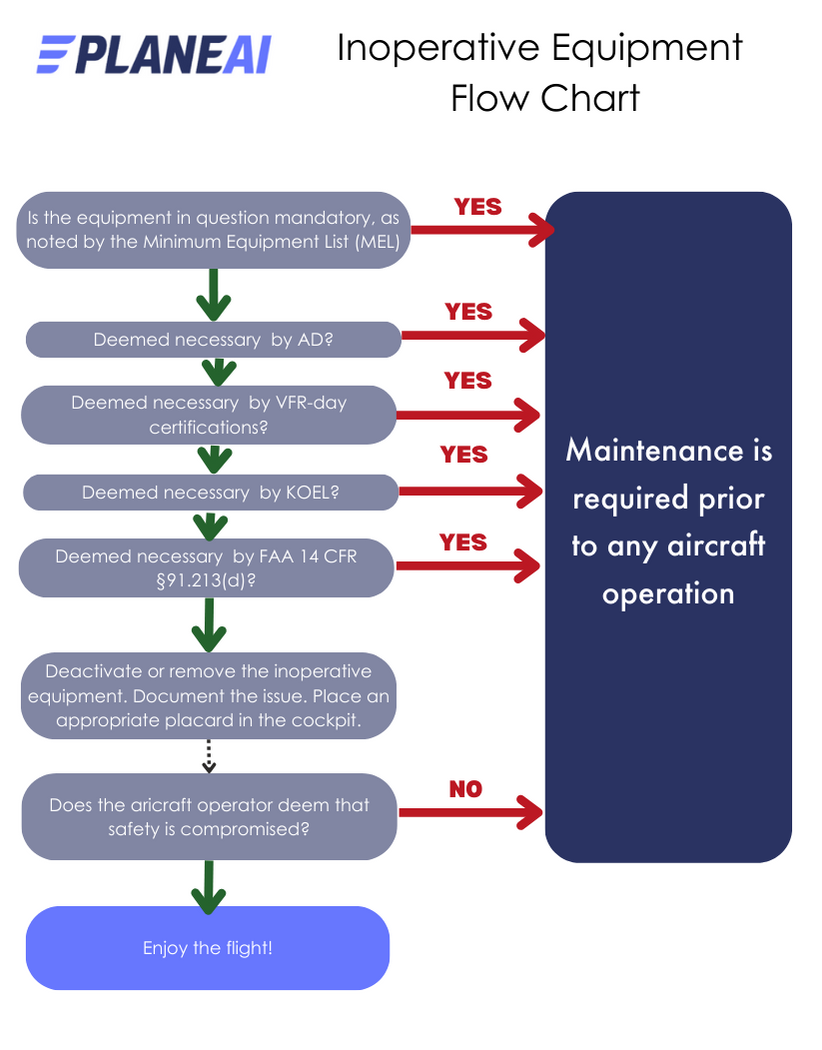

In short, this flowchart is a visual representation of a decision-making process that maintenance crews and pilots use to determine whether an aircraft can be deemed airworthy despite having certain equipment not functioning. It incorporates various factors, such as the nature of the inoperative equipment, its impact on flight operations, safety protocols, and regulatory compliance.

The flow chart typically starts with identifying the inoperative item and then branches into different pathways based on several criteria. These criteria include the equipment’s criticality, availability of redundant systems, flight conditions, and regulatory allowances. Each path leads to a decision: whether to ground the aircraft for immediate repair, defer the repair to a later time, or proceed with the flight as planned.

The Purpose and Significance of These Flow Charts in Aviation Maintenance

The primary purpose of an inoperative equipment flow chart is to ensure flight safety while maintaining operational efficiency. It is a tool for making informed decisions that balance the need for timely flights with uncompromising safety priority. Following the flow chart, maintenance teams and pilots can quickly determine the best course of action, ensuring no aircraft is flown with compromised safety.

These flow charts are also significant for regulatory compliance. Aviation authorities like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) have stringent regulations regarding aircraft airworthiness. The inoperative equipment flow chart helps adhere to these regulations by providing a standardized method to evaluate and handle inoperative equipment.

Moreover, these flow charts contribute to cost-effectiveness and efficiency in aviation operations. By allowing certain non-critical repairs to be deferred within the bounds of safety and regulatory guidelines, airlines can avoid unnecessary groundings and delays, thereby saving on costs and maintaining flight schedules.

How Inoperative Equipment Flow Charts Work: Step-by-Step Breakdown of the Flow Chart Process

- Identification of Inoperative Equipment – The process begins with identifying the equipment that is not functioning properly. This could be discovered during routine checks, reported by the flight crew, or flagged by onboard diagnostic systems.

- Assessment of Equipment Functionality – Once identified, the next step is to assess the functionality of the equipment. This involves determining whether it is completely inoperative or partially functional and understanding its role in aircraft operation.

- Ensure Compliance With MEL Guidelines– The Minimum Equipment List (MEL for short) specifies which equipment is necessary to safely operate the craft. While originally crafted by the operator, it undergoes FAA approval.

- Review Other Regulatory Requirements – This includes Airworthiness Directives (AD), VFR-day certificates, Kinds of Operation Equipment List (KOEL), and FAA guidelines 14 CFR §91.213(d).

- Consultation of the Aircraft Maintenance Manual (AMM) – The AMM, specific to each aircraft model, contains detailed guidelines on handling various equipment failures. It is consulted to understand the recommended actions for the identified issue.

- Determination of Flight Safety Impact -This critical step involves evaluating how the inoperative equipment impacts flight safety. Factors considered include whether the equipment is critical for flight if redundant systems exist and the flight conditions under which the equipment is essential.

- Decision on Action – A decision is made based on the above assessments. Options include grounding the aircraft for immediate repair, deferring the repair (as per MEL guidelines), or proceeding with the flight if safety is not compromised. Regardless, the inoperative equipment must be either removed or deactivated, and an appropriate placard must be placed within the cockpit.

Documentation and Communication – Any decision is thoroughly documented, and relevant parties (such as flight crew, maintenance teams, and regulatory bodies) are informed.

Hypothetical Examples Of The Decision-Making Process Using An Inoperative Equipment Flow Chart

Example 1: Inoperative Cabin Lighting

- Identification: Cabin lights in row 15 are not working.

- Assessment: The lights are completely inoperative.

- AMM Consultation: AMM suggests this is not critical for flight.

- Safety Impact: No direct impact on flight safety.

- Regulatory Reference: Per MEL, this issue can be deferred.

- Decision: Defer repair; document and inform the crew.

Example 2: Faulty Autopilot System

- Identification: The autopilot system is not engaging.

- Assessment: A key component of the system is malfunctioning.

- AMM Consultation: Indicates criticality for long-haul flights.

- Safety Impact: Essential for reducing pilot workload on long flights.

- Regulatory Reference: FAA guidelines require immediate attention.

- Decision: Ground the aircraft for quick repair; document and communicate the decision.

These examples show how the inoperative equipment flow chart guides maintenance teams in making informed, safety-centric decisions. It ensures a standardized approach to handling equipment issues, maintaining the delicate balance between operational efficiency and uncompromising safety in aviation.

Importance of Inoperative Equipment Flow Charts

Ensuring Flight Safety and Regulatory Compliance

The foremost importance of inoperative equipment flow charts lies in their role in ensuring flight safety. By providing a well-structured approach to evaluating and handling inoperative equipment, these charts help maintenance teams and pilots make decisions that prioritize safety above all else. They ensure that no aircraft is cleared for flight unless it meets the stringent safety standards of aviation authorities.

Additionally, these flow charts are crucial for regulatory compliance. Aviation is a highly regulated industry, and adhering to the standards set by bodies like the FAA and EASA is non-negotiable. The flow charts are designed in alignment with these regulations, ensuring that all decisions regarding inoperative equipment are compliant with legal requirements. This compliance is not just about following rules; it’s about maintaining a culture of safety that is fundamental to aviation.

Role in Maintenance Decision-Making and Operational Efficiency

Inoperative equipment flow charts provide a clear, concise framework for maintenance teams, eliminating guesswork and subjective judgment. This standardized approach leads to more consistent and efficient decision-making, crucial in a field where precision and accuracy are paramount.

Operational efficiency is another critical aspect. These flow charts help quickly determine whether an aircraft can safely continue operations or needs to be grounded for repairs. This efficiency is vital for airlines and aviation companies, where time is valuable. Efficient decision-making helps maintain flight schedules and reduce disruptions, which is beneficial not just for the airlines but also for the passengers.

Impact on Minimizing Downtime and Cost-Effectiveness

Finally, using inoperative equipment flow charts significantly minimizes aircraft downtime and enhances cost-effectiveness. By allowing for the deferral of certain non-critical repairs, these charts help keep aircraft operational, thereby reducing ground time. This approach is cost-effective as it avoids the expenses associated with unnecessary groundings and delays.

Moreover, by ensuring that repairs are carried out only when absolutely necessary and in compliance with safety regulations, these charts help in optimizing maintenance costs. This cost-effectiveness is crucial in an industry where financial margins can be tight and operational costs are high.

Key Takeaways About Inoperative Equipment Flow Charts in Aviation Maintenance

Maintaining the highest safety and efficiency standards is paramount in aviation’s vast and intricate world. We’ve seen how these flow charts are crucial in the maintenance toolkit, guiding professionals in making informed decisions and managing aviation risks. They ensure that every piece of equipment, whether operative or not, is meticulously assessed and addressed, keeping in line with stringent safety and regulatory standards.

In an industry where precision and accuracy are non-negotiable, these flow charts provide a clear pathway to maintaining the highest aircraft safety and reliability standards. Their use is a clear indicator of a maintenance team’s dedication to excellence and a reflection of the industry’s overall ethos. Embracing these flow charts and the principles they embody is more than just adopting a tool; it’s a commitment to upholding the legacy and prestige of the aviation sector.

Written by Michael Olusoji

Michael Olusoji is a distinguished aviation writer with over five years of in-depth expertise.

His comprehensive research and analytical prowess have culminated in a myriad of articles that dissect the intricate facets of the aviation sector, particularly the engineering nuances of aircraft components.