Maintenance is one of the most pressing parts of running a flight operations department. And one of the key parts of every aircraft maintenance operation is supply. We see it in the military; we see it in the civilian sector. Without a robust supply chain, your flight operations department doesn’t exist. It comes to a screeching halt.

As time moves on, methods evolve as well. The tactics used 10 to 20 years ago for parts inventory management have been completely eclipsed by implementing modern digital alternatives. Now is the time to evaluate your own company’s inventory management practices in light of new technologically driven possibilities to ensure maximum efficiency and accuracy.

Understanding Problems With Legacy Supply Systems

Are you still tracking inventory manually? Researchers found that for every 300 characters, a data entry operator makes one error. And because you probably carry hundreds of thousands of stock items, this can cause a major headache. Automated processes increase efficiency, improve accuracy, and are scalable to company growth.

Using an Excel file is slow, inaccurate, and does not allow multiple users to access it simultaneously. By automating your inventory management, you will be able to see how your employees track various items across numerous locations, all while monitoring orders and shipments for those items.

To further drive home the shortcomings of legacy supply systems, I can share a firsthand account of my time as a jet aircraft mechanic in the US Air Force, working on B-1B bombers.

If you’ve been around aviation, the B-1 is a fantastic airplane. Beautiful, sleek, and very fast, but it is a maintenance nightmare. It was built by hundreds of vendors and originally designed and built by Rockwell, which no longer exists; also, many of the vendors no longer exist. Since it’s a unique, large aircraft, it doesn’t share many commonalities regarding parts and components with anything else.

Due to this, the supply chain for the B-1 has always been a train wreck, and as long as it’s in service, it will always be a train wreck.

So, there is a constant strain on the supply system because there were insufficient replacement parts to keep the fleet operating. But, in addition to this, there were hundreds upon hundreds of man-hours of keeping the warehouses with parts. In the late 1990s in the early 2000s, when I worked on the airframe, we were using computerized methods, but the technology was still very much of the late 1990s Windows-based systems.

Searching for parts was a paper-based hunt, and some technical manuals were in PDF format, but for the most part, researching parts took hours and involved diving into extensive technical manuals.

Once we had a stock number and a part number, then we’d have to take it to a supply specialist, who would then transfer that into something that would translate into their system.

As the name suggests, aircraft parts inventory management is the highly technical field of tracking millions of individual parts’ inbound, storage, and outbound status. This is a tall order for any organization, especially when the stakes are this high.

What is the most frustrating thing of all about ordering parts? Here’s an anecdote that we can all relate to:

You need a part for your car, something really basic like a hose. So you quickly hop on the Big Box store website, which boasts that 23 options are available. But then you go through the list more carefully and find out that there are only two in-store options, and they are both actually out of stock at the moment. So, even though the stock website says you can get a radiator hose, you aren’t really getting one.

Solutions like ePlane Can Help Remedy Such Issues

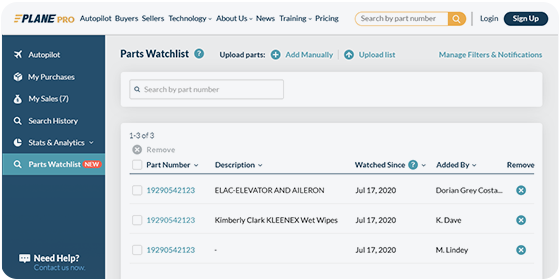

ePlane takes great pride in our Marketplace solution. When you log into our Marketplace, you will know that every quarry brings up only immediately available items.

ePlane’s marketplace and underlying technology benefit your aircraft inventory management by:

- Enabling real-time/daily sync from the seller’s ERP (Spec 2000 and other custom protocols)

- Listing all parts by serial numbers (no duplications)

- Adapting to your frame agreements

Our live chat feature puts you in contact with buyers or sellers, so you can get answers clarified or finalize your deals with just a few clicks.

You can send and receive RFQs, quotes, POs, and invoices, review and manage the pertinent documents all in one place, and every transaction is logged for use down the road. The ePlane Marketplace is open and available all day, every day, from anywhere globally.

Understanding How Are Aircraft Parts Currently Inventoried?

Today, aircraft parts are inventoried using a variety of methods, including:

- Manually, by tracking parts on paper or spreadsheets

- Using barcodes or RFID tags to track parts electronically

- Using computerized inventory management systems

The method used to inventory aircraft parts will vary depending on the size and complexity of the organization, the number of parts in inventory, and the level of detail required.

Manual inventory tracking is the simplest and least expensive method but also the most time-consuming and error-prone. Barcodes and RFID tags can automate the tracking process and make it more accurate, but they can also be expensive to implement. Computerized inventory management systems offer the most flexibility and accuracy but can also be the most expensive to implement.

The best method for inventorying aircraft parts will vary depending on the organization’s needs.

Traditionally, Part Inventory Management Relied Heavily On Manual Inputs

There are still plenty of old-school warehouses out there that keep their balances on paper ledgers. While there is not necessarily anything wrong with this, it opens the door wide for human inaccuracy and error in their aircraft parts inventory management.

How so?

Well, let’s take a look at any typical warehouse. Even if it is a small supplier, there could still be upwards of half-a-dozen people (but probably way more) working at any given time. Suppose their inventory strategy uses manual input in a paper ledger or a simple system like an Excel spreadsheet. In that case, the warehouse team must be on the same page about tracking inventory. Otherwise, errors will occur.

The best way to reduce errors in your aviation inventory management is by adopting and using our Marketplace platform.

Give More Time To Your Work and Less Time To Your Inventory With ePlane

The ultimate goal is to put hours where they are most useful, and inventory management can be time-consuming if you aren’t careful.

We at ePlane have worked tirelessly to provide business solutions that cut the time you put into inventory management while increasing accuracy. That’s the best part: by deploying the tools at our disposal, you will have more time to put back into your main goal with the knowledge that your inventory is being tracked with much higher accuracy than by manual inputs.

ERP System Integrations

Our solution for sellers is an end-to-end platform that combines all inventory and capabilities. ePlane will sync with your EPR system and handle everything in the selling process. We offer a single, user-friendly interface that handles it all.

Don’t worry; it all goes on seamlessly any hour of the day or night, all the time. Do you have clients on the other side of the world ordering parts? Now, their order isn’t going to sit around in the inbox waiting for manual processing; ePlane handles the whole process to queue the order and get it rolling.

In-Platform Live Chats

Interfacing between buyers and sellers can play an important role in arranging transactions and granting peace of mind to both parties. Through our in-portal interface, you can securely negotiate terms and conditions, send and receive documents & POs, and send out invoices.

Access to Industry Statistics and Personal Sales Analytics

Another standard feature of our programs is Stats & Analytics. In order to effectively manage both your budget and aircraft inventory, you should know where the market is headed, trends, benchmarks, pricing, etc. You will get all of these features and more in our comprehensive dashboard.

SSL Encrypted Payment System for Top Security

Finally, payments. All payments are secure, and SSL encrypted, making it completely safe and secure. You can receive either wire transfers or credit card payments. Best of all, our registration is entirely free. No subscription fee, no commissions.

You can start listing your inventory for free, sell your aircraft parts and/or services without paying commissions, and you won’t have to pour money into expensive marketing campaigns to broaden your client base.

Common Mistakes to Avoid in Aircraft Parts Inventory Management

Inventory planning is an art form. Done correctly, it can save your business big bucks and valuable time. Done wrong, – aircraft parts being purchased and not meeting projected rotations – the inventory goes from being an asset to becoming a liability.

1. Your Employees Are Not Sufficiently Qualified

Nothing causes monetary leakage quite as much as disorganization in your warehouses. If your employees are not properly trained and qualified inventory management specialists, working within standard parameters using appropriate inventory management software, you can say goodbye to millions of dollars. s.

Storing different categories, such as aircraft parts, components, consumables, chemicals, lubricants, and retables, calls for different methods and conditions. Unnecessary damage can be avoided when you know how to keep each item. Aircaft inventory specialists with proper background and knowledge can maintain optimal storage conditions.

Overstocking and understocking are also lethal for your business. Buying aircraft parts and planning aircraft inventory are two different things that require two different skill sets and therefore should be taken care of by separate departments. A buyer’s objective is to purchase, while a planner’s objective is to achieve your materials-in-stock goals.

Hire people with the right experience, hold managers accountable for their department, separate your aircraft parts buying and planning activities, and make sure you train your staff initially and periodically.

If your employees are not qualified aircraft parts inventory management specialists, you can say goodbye to up to millions of dollars.

2. Too Many Part Numbers All Over the Place

Aircraft parts stock accumulation is something that happens naturally over time. We know that. Ideally, this situation must be decreased to a minimum, using strategic tools. Usually, you can spot a problem when there’s a scramble while filling lower-volume items, or when 20% of your high-usage PNs no longer account for 80% of your demanded items.

Having no stocking policy is also a problematic issue. Your specialists must facilitate a control-focused procedure for stocking each item in a specific warehouse or station.

When procurement departments overshadow planners, part number levels are not tracked, and the stacks will start piling up. A smart inventory planning policy will enforce your buyers to supply a reason for stocking an item and diminish clutter.

3. You Do Not Invest in Your Vendors

One of the biggest mistakes inventory mistakes is not nurturing the relationships with vendors. In every procurement-based business, 20% of the suppliers account for 80% of the growth. You must identify those ‘growth engines’ and do your best to establish mutual trust with each and every one of them. You need these vendors. Moreover, their performance is a direct result of how your operation is running.

AOG is stressful, we know. However, creating more stress by demanding, micro-managing, and being aggressive with your vendors will not solve the problem. It will widen the gap and earn you a dissatisfied, disloyal supplier.

Start developing effective communication skills by keeping the channels open, sharing your business goals, and discussing problems as they arise. It is the best way to ensure mutual success.

Meet with your top aircraft parts vendors quarterly and present them with a performance review. Talk with your dedicated Account Manager often, not only when there is an issue or crisis. Make sure your employees create an open, solution-oriented dialogue with all vendors.

Meet with your top aircraft parts vendors quarterly and present them with a performance review.

4. You Do Not Measure Your Performance

It’s not hard to detect a downward trend. Your

No matter if it’s the speed your aircraft inventory moves through the various delivery stages that

Incorporate mandatory tracking of fill rates and inventory turns. Your Material Managers should know these numbers. Make sure you track fill rates daily, monthly and quarterly. Inventory-turn tracking frequency differs according to your operations. After you have sufficient stats, it’s time to delve into the insights and draw conclusions; is your aircraft parts inventory serving the demands your business receives? Or are you putting your focus on the wrong items?

Look at the current consumption patterns; what is being sold and when, the quantity you distribute per item, per client, etc. Once you have all the accurate stats, it is easier to foresee what next year will look like. There WILL be deviations, but as long as your predictions are based on real data, you should not be off target.

Track fill rates & turns; is your aircraft parts inventory serving the demands your business receives? Or are you putting your focus on the wrong items?

5. No Aircraft Part is the Same

We mentioned this point earlier. Different part numbers require different storage conditions. Not all items are consumed in the same quantity or rate. It is wrong practice to handle C items like they were A items.

The best way to set correct goals for each part number is to implement an ABC analysis, manage each material differently, and to use safety time as a key parameter in your aircraft inventory planning (rather than safety stock).

Most organizations utilize safety stock (an additional quantity of an item held in inventory in order to reduce the risk that the item will be out of stock) as a key component in their inventory planning. However, this can be ‘hit and miss’ when markets shift and technology progresses.

While safety stock is used to provide a buffer for demand variation, safety time provides a buffer for delivery and lead time variation. When you use safety time as the leading indicator, you bring in aircraft parts inventory prior to the time it is actually needed.

When safety time is used, the average inventory is one-half the replenishment quantity plus the remaining existing inventory on-hand when the replenishment quantity is delivered. As a result, you carry much lower safety inventory quantities.

An excellent strategy to improve inventory performance and turnover is to use safety time on slower-moving B and C items. This practice provides a level of safety coverage late in the replenishment cycle when stockouts are more likely to occur.

Automate your aircraft parts inventory system and see how your employees track various items across numerous locations.

6. You Do Not Count Your Inventory Often Enough

Sure, your team checks inventory levels every so often, but do they count EVERYTHING periodically? Counting your entire inventory is crucial to the calculation of one of the most important financial indicators for your business – Cost of Goods Sold (COGS). COGS can account for up to a third of your total expenses. So yes – it can make or break your business.

We know that this can delay the work but, if you check one section per day, you won’t have to shut down the entire operation.

Counting your entire aircraft parts inventory is crucial to the calculation of the Cost of Goods Sold (COGS).

7. Your Internal Communication is Failing

If your managers are used to operating in silos – it can be lethal to your aircraft parts inventory management.

For example, if your Procurement Manager has separate goals from those of your Maintenance Manager, your business will have to endure either overstocking or insufficient supply.

Each and every one of your department managers must operate together as a single, cohesive unit. Set weekly syncs, make sure everyone is in the loop, and encourage open communication channels at all times.

8. Your Shelves Are Disorganized

Order vs. chaos. Such an important factor in life. And when managing aircraft parts inventories, it can save your business. How much time, on average, does it take your warehouse workers to find a part number? We encourage you to time them. Can you imagine how much money you can save if you diminish this time to a minimum?

When you implement structured storage systems inside your aircraft parts warehouses, productivity will increase. Use pre-draw kits for routine check-ups at arm’s reach, store highly-used expendables closer to the technicians, and keep no-go MEL rotatable in a quick-to-access space.

And most importantly: lose the clutter! Your aircraft spare parts array does not have to be all-encompassing. You do not need thousands of items from the same unique PN. For better control over your aircraft inventory, you need to define and categorize airplane spare parts. What can be labeled ‘critical’ and must be on hand? Which PNs are negligible and can be ordered upon request?

Key Takeaways About Avoiding Parts Inventory Management Mistakes

The quickest way you can run your business into the ground is by not adapting and updating management procedures for your airplane parts inventory.

Have you been doing the same thing for 20 years? If so, most chances are you are managing your aircraft parts inventory inefficiently. Whether you own a two-man shop or a 1,200+ person repair station, we advise you to use these nine guidelines as a framework. They will help identify pitfalls and build a management process that will keep customers satisfied, vendors communicating and employees engaged – all which result in a better-run, profitable business.

Have you developed your own inventory management strategy? Email us! We would love to hear more about it.

Ready To Change How Your Business Does Aviation Inventory Management? Connect with ePlane

There’s no time like the present to evolve how your business handles aircraft parts inventory management, improving both the time it takes and the quality of insights you glean. We make it possible with ePlane’s end-to-end solution that handles payment processing, automated inventory management, buying and selling, and everything in between.

Your bottom line gets cut into every time there is an inventory management issue, a payment processing failure, or miscommunication due to convoluted communications systems. Consolidating the procurement and selling of parts into a singular platform grants the ease and visibility you need to troubleshoot problems and maximize returns.

Don’t have an account yet? Join ePlane now.

Are you looking to learn more about topics related to aviation inventory management? Read:

- Aviation Risk Management Strategies for 2024

- Fire Extinguishers for Aircraft- Types & Considerations

- Aircraft Corrosion – Filiform, Pitting & Other Corrosion Types

- Cessna 182 vs. 172 – Cruise Speed, Cabin Size & More

- Current Aviation Trends and the Future of the Airline Industry

Written by John McCoy

John McCoy is a professional copywriter focusing on aviation and aerospace. He spent over two decades in the aviation industry, working in many different capacities and roles in administration, airport operations, and aircraft maintenance, along with being a private pilot. These experiences give him a unique vantage point on all things aviation.